Chain driven roller conveyors as great for handling heavy product with smooth bottom or on pallets.Chain driven roller conveyor are used for warehouse operation handling steel sheet,structure shapes,using pallets or skids.A very versatile conveyor for package handling,accumulation ,automobile tire handling systems and parts with flat or smooth bottoms transfer systems.

Motorized rollers (MDR) are conveyor rollers with their own internal motors.Each motor roller controls a small zone of free-turning rollers.This inherently modular design makes designing and building a Zero Pressure Accumulation conveyor systems faster and easier than coinventional conveyor system.

Benefits

The Pulse Roller motor driver modules each provide full feature brushless DC motor commutation in a convenient package. They provide motor control and protection for virtually any motor roller, multiple electronic braking functions, speed selection, acceleration and deceleration control. The core of this system is the Powered Roller Control Module, which is designed using smart functions that are built into the module that provide control of various opeartion modes of the drive modules.

The polycord driven curve conveyor is a low cost,simple to use safe product for transporting non wash down items.The quiet and efficient cost saving operation and product energy saving due to module slave driver for certain conveyor length within it capacity.

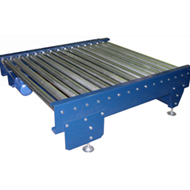

Roller conveyor are used for transporting products on either horizontal push or declined lines, the latter using the natural gravity force and it's sometime known as gravity roller conveyor. Low initial cost and minimum maintenance are the main advantages of the roller conveyor.

Wheel conveyors utilise skate wheels for light-weight product conveyance. Manual movement of products on wheel conveyor is easy due to the light weight of the wheels.